The Production Process of Handbags

In this article, we will explore the production process of handbags, giving you an insight into how they are created from start to finish. You will learn about the materials used, the various stages involved in assembly, and the techniques employed to ensure the high quality of the final product. By the end, you will have a better understanding of the intricate craftsmanship involved in producing the handbags we use and love.

Design and Conceptualization

When it comes to producing handbags, the first step is to have a clear design and concept in mind. This involves conducting market research and trend analysis to determine what styles, colors, and features are currently popular among consumers. By staying updated with the latest fashion trends and understanding the demands of potential customers, you can create a design that is appealing and has a high chance of success in the market.

Once you have an idea of what you want your handbag to look like, it’s time to conceptualize the design. This involves sketching and drawing different variations of the handbag to explore different possibilities and refine the design. During this stage, it’s important to consider not only the aesthetics but also the functionality and practicality of the handbag. You want to create a design that not only looks good but also meets the needs of potential customers.

Material Selection

After finalizing the design, the next step is to select the materials that will be used for the handbag. This includes sourcing high-quality fabrics and leather that will give the handbag a premium look and feel. The materials should be durable and resistant to wear and tear to ensure that the handbag will last for a long time.

In the case of leather handbags, additional processing and treating may be required to enhance the quality and appearance of the leather. This involves treating the leather with oils or dyes to achieve the desired color and texture. For fabric handbags, dyeing and printing may be necessary to add color and patterns to the fabric.

In addition to selecting the main materials, it’s also important to prepare the hardware and accessories that will be used for the handbag. This includes items such as zippers, closures, straps, handles, and decorative embellishments. These components should be of high quality to ensure that the handbag is not only visually appealing but also functional and durable.

This image is property of images.unsplash.com.

Pattern Making and Prototyping

Once the materials have been selected, the next step is to develop the pattern for the handbag. This involves creating a template or blueprint for cutting the materials and assembling the handbag. The pattern should be precise and accurate to ensure that all the pieces fit together properly during the assembly process.

After the pattern has been developed, the materials can be cut according to the pattern. This can be done manually or with the help of machines, depending on the scale of production. Once the materials have been cut, the prototype of the handbag can be assembled.

During this stage, it’s important to test the prototype and make any necessary modifications to improve the design or functionality of the handbag. This may involve adjusting the size or shape of certain components, making changes to the placement of pockets or compartments, or tweaking the overall construction of the handbag. The goal is to create a prototype that is a true representation of the final product and meets the expectations and requirements of potential customers.

Production Planning and Organization

With the prototype finalized, the next step is to plan and organize the production process. This involves estimating the production costs, determining the quantity of handbags to be produced, creating a production timeline, and allocating the necessary resources and labor.

Estimating production costs is crucial for determining the retail price of the handbags and ensuring that the production process is financially viable. This includes considering the cost of materials, labor, overhead expenses, and any other associated costs.

Determining the production quantity involves considering factors such as market demand, production capacity, and expected sales. It’s important to strike the right balance between producing enough handbags to meet customer demand without overproducing and risking excess inventory.

Creating a production timeline helps to ensure that the production process stays on track and that the handbags are produced within the desired timeframe. This involves setting deadlines for different stages of production, such as cutting and stitching, embellishments and details, quality control, and packaging.

Allocating the necessary resources and labor is important for efficient and smooth production. This includes determining the number of workers needed, their roles and responsibilities, and ensuring that all the necessary tools and equipment are available.

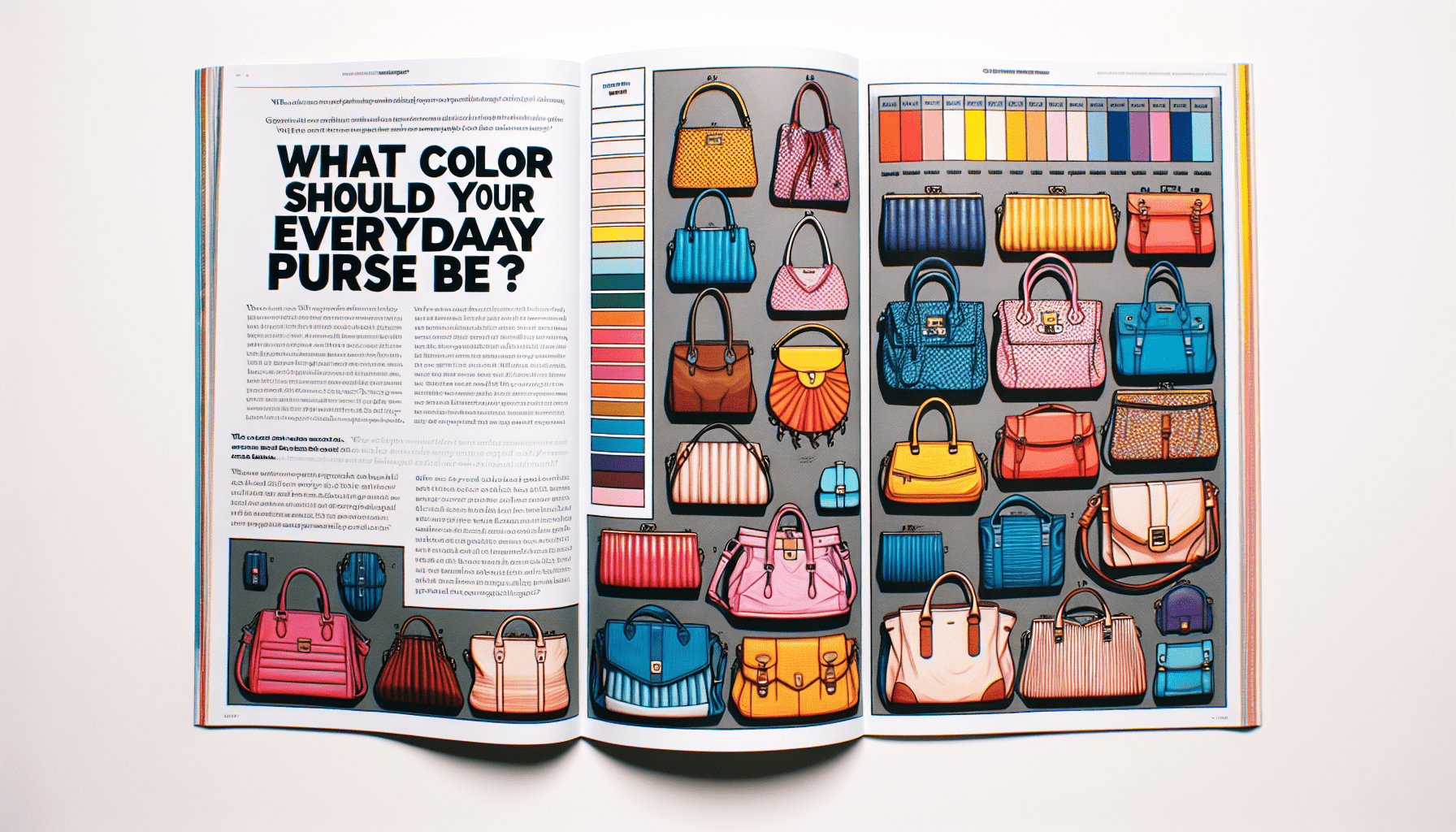

This image is property of images.unsplash.com.

Cutting and Stitching

One of the most crucial stages in the production process is cutting and stitching the materials to create the main bag panels. This requires precision and attention to detail to ensure that all the pieces are cut accurately and that the stitching is strong and durable.

First, the fabric or leather is cut according to the pattern, taking care to follow the designated measurements and markings. This can be done manually with the use of cutting tools or with the help of cutting machines for larger scale production. Accuracy is key during this stage to ensure that all the pieces fit together seamlessly during the assembly process.

Once the pieces have been cut, the main bag panels are stitched together. This involves using sewing machines or hand stitching techniques to join the panels using strong and durable stitches. The stitching should be neat and even, and any seams or edges should be finished properly to prevent fraying or unraveling.

Embellishments and Details

After the main bag panels have been stitched together, it’s time to add the embellishments and details that will enhance the overall design of the handbag. This includes attaching zippers and closures, applying decorative embroidery, inserting interior lining, and attaching brand labels and tags.

Zippers and closures are essential for securing the contents of the handbag and adding a functional element. They should be of high quality to ensure smooth operation and durability. Decorative embroidery can be added to enhance the visual appeal of the handbag and give it a unique and personalized touch. Interior lining is important for protecting the contents of the handbag and adding a luxurious feel. Brand labels and tags are necessary for branding and communicating important information about the handbag, such as the materials used and care instructions.

This image is property of images.unsplash.com.

Quality Control and Finishing

Once all the components have been added and the handbag is complete, it undergoes a thorough quality control process. This involves inspecting the stitching and seams to ensure that they are secure and free from any defects. Zippers and hardware are tested to ensure smooth operation and functionality. The overall appearance of the handbag is examined for any imperfections, such as loose threads or uneven stitching.

Any necessary adjustments or repairs are made to fix any imperfections or defects. This may involve re-stitching certain areas, patching any holes or tears, or reattaching loose hardware or embellishments. The goal is to achieve a high level of quality and ensure that the handbag meets the expectations and standards set by the brand.

Packaging and Labelling

Once the handbags have passed the quality control process, they are ready to be packaged and labeled. Choosing the right packaging materials is important for protecting the handbags during transportation and storage. This may include using boxes, dust bags, or protective covers made of materials such as cardboard or fabric.

The handbags are carefully folded and packed using the appropriate packaging materials. Any necessary care instructions and tags are added to provide important information to customers, such as how to clean and maintain the handbag. Barcodes and labels are applied to help with inventory management and tracking.

Distribution and Marketing

The final stage in the production process is the distribution and marketing of the handbags. This involves identifying target markets and creating marketing strategies to promote and sell the handbags. Distribution channels are established to ensure that the handbags reach the intended customers in a timely manner.

Showcasing and promoting the handbags is important for generating interest and attracting potential customers. This can be done through various channels, such as online platforms, physical stores, trade shows, or fashion events. The goal is to create brand awareness and generate sales through effective marketing and distribution strategies.

Conclusion

The production process of handbags is a complex and intricate one that involves various stages and careful attention to detail. From the initial design and conceptualization to the final distribution and marketing, every step plays a crucial role in creating high-quality and stylish handbags that meet the demands and expectations of customers. By following a well-defined production process and staying updated with the latest fashion trends, handbag manufacturers can ensure that their products are successful in the market and meet the ever-changing needs of consumers.